Description

Grounding Earthing And Bonding

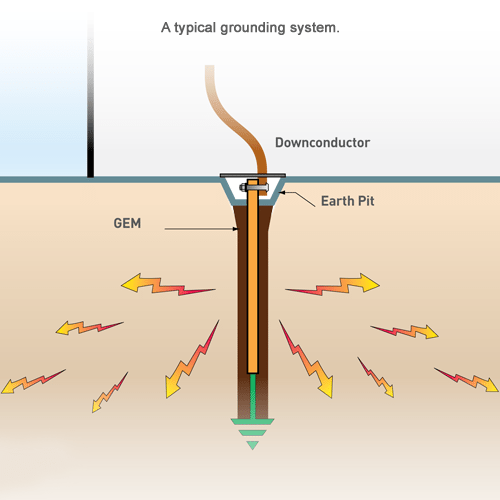

Grounding and bonding are an integral part of any modern electrical protection system design. An effective, low-impedance ground system is a key element of this system. It is crucial to help provide personal safety, as well as reliable protection for vital equipment and to minimize interruptions of service and costly downtime. With over a century of experience in the design and manufacture of bonding and grounding products, ERICO, a single source provider, offers what we believe is the best range of long lasting and cost-effective grounding products available.Soil conditions and seasonal patterns vary from site to site, the methods of grounding need to be considered on an individual basis.

- Ground: A conducting connection, whether intentional or accidental, between an electrical circuit or equipment and the earth, or to some conducting body that serves in place of the earth.

- Earth: The conductive mass of the earth, whose electric potential at any point is conventionally taken as equal to zero. In some countries the term “ground” is used instead of “earth.”

- Bond: The permanent joining of metallic parts to form an electrically conductive path that will ensure electrical continuity and the capacity to conduct any current likely to be imposed.

The need to ground!

There are important reasons why a grounding system should be installed.

- The most important reason is to help protect people!!

- To help provide protection of structures and equipment from unintentional contact with live conductors.

- To help support maximum safety from electrical system faults and lightning.

It is a fundamental fact that electricity ALWAYS flows to the point of lowest potential. The task is to help ensure that electricity, including faults, lightning and electronic noise, flows to this point with maximum safety to people while maintaining the reliability of equipment. Therefore we must help ensure the safe, controlled flow of electricity with minimum voltage drop to earth in all cases.

Grounding Codes and Standards

Grounding needs vary according to function. The grounding requirements of a power system will vary from those of electrical equipment, lightning protection or for the proper function of electronic equipment.Proper installation of appropriate grounding systems requires knowledge of the needs and layout of the facility. Soil characteristics, grounding conductor materials grounding connections and terminations, are significant factors determining the design of a grounding system. Applicable standards and codes must be applied.

While many codes and standards contain minimum grounding and bonding requirements, the design and installation of electrical grounding systems is one of the most important aspects of any electrical distribution system. However, codes and standards are often misunderstood and grounding systems subsequently installed improperly.

ERICO offers a variety of products, such as ground bars, signal reference grids, ground plates and potential equalization clamps, which are designed to create an equipotential plane and help protect personnel and valuable equipment.ERICO CADWELD copper-bonded or stainless steel earth rods and GEM facilitate the transfer of surges and fault currents into the earth, and provide a very long service life due to superior construction and quality.

Grounding Principles

Ground Impedance

Soil resistivity is an important design consideration. It varies markedly for different soil types, moisture content and temperatures, and gives rise to variations in ground impedances.

Short, Direct Ground Connections

The voltage generated by a lightning discharge depends primarily on the rise time of the current and the impedance (primarily inductance) of the path to ground. Extremely fast rise times result in significant voltage rises due to any series inductance resulting from long, indirect paths, or sharp bends in the routing of ground conductors. This is why short, direct ground connections are important.

Coupling from the Electrode System to the Ground

The efficiency of a ground electrode system in coupling a lightning current to ground is dependent on a number of factors, including the geometry of the ground electrode system, the shape of the conductors and the effective coupling into the soil.

The basic philosophy of any grounding installation should be an attempt to maximize the surface area of electrodes or conductors with the surrounding soil. Not only does this help to lower the earth resistance of the grounding system, but it also greatly improves the impedance of the grounding system under lightning surge conditions.

Contact Our Grounding & Earthing Expert Richard Walker